The Heat Is On: How High-Quality Thermal Cameras See Threats That Other Solutions Cannot

Thermal sensors capture something that the naked eye cannot see: heat. What distinguishes thermal cameras from other security sensors is their ability to use heat rather than light to produce images. By measuring the differences between heat signatures and representing these variances in high-contrast, monochrome images, thermal cameras can “see” even in total darkness, sun glare, rain, light fog, smoke and other adverse conditions.

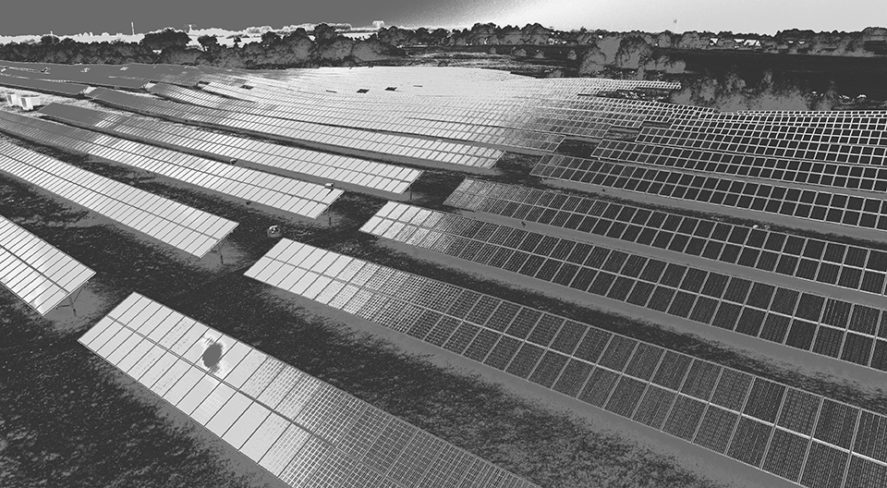

While a standard surveillance camera may not be able to spot a camouflaged suspect in foliage at night, a thermal camera will easily see the person. This is one of the reasons why thermal cameras have become essential tools for detecting intruders, securing borders, and safeguarding airports, seaports, power plants, electric substations and other critical infrastructure sites.

Demand for Advanced Detection

Following the terrorist attacks of Sept. 11, 2001, mission-critical enterprises expressed increased interest in thermal cameras to enhance intrusion detection at their properties, particularly at night.

In the 2010s, the Nuclear Regulatory Commission announced its 73.55 policy, which states that nuclear facilities must “provide continuous surveillance, observation and monitoring” to improve threat recognition and crime deterrence. Thermal cameras, given their ability to produce clear images in bright light, low light and no light at all times of day and night, quickly became a preferred option for the nuclear industry.

The 2013 sniper attack on Pacific Gas & Electric’s Metcalf Transmission Substation in Coyote, California, led the Federal Energy Regulatory Commission to introduce Critical Infrastructure Protection Standard 014 (CIP-014). This standard requires utilities to deploy advanced security systems to identify and mitigate threats to mission-critical assets.

Thermal cameras have become attractive options for utilities because of their long-range capabilities and ability to detect intruders before they reach the fence line. Another advantage is their simple installation. Thermal cameras can be mounted on existing walls and lattices, whereas other solutions, like buried cable sensors, may require trenching and other extensive labor. For these reasons, thermal cameras have frequently been added to the security systems of power plants and substations across the country. Today, thermal cameras have become the go-to perimeter monitoring solution at critical infrastructure sites.

The Market for Thermal Solutions Expands

Thermal cameras have often been considered a niche technology for high-end security applications. However, their success in the industrial and critical infrastructure sectors has generated demand across a variety of verticals.

In 2017, revenue for the thermal imaging market surpassed $5.5 billion, according to Global Market Insights, and by 2024 the market is predicted to nearly double to $10 billion. This growth reflects integration with various other technologies, including unmanned aerial vehicle deployments by the military, handheld devices sold to critical infrastructure sites and cooled cameras, which offer superior imaging for life sciences, health care, special industrial detection and automotive applications.

The growing interest in thermal technologies can be seen in the security sector, as both traditional and new camera suppliers have debuted their own lines of thermal cameras over the past five years. This mushrooming of the market for thermal devices reflects a growing interest in thermal’s value proposition and affirms the demand for innovative technologies that take security solutions to the next level.

Distinguishing Features of Superior Thermal Technology

While there are many thermal camera options available today, it is essential that systems integrators and end users alike understand how to distinguish a first-rate thermal camera from a lower-tier one. Cutting costs upfront often does not pay off in the long run.

A low-end thermal camera can experience video degradation over time. As a result, low-quality images, inaccurate detection and maintenance calls to fix these issues can increase the total cost of ownership. As a best practice, security practitioners should implement high-quality thermal cameras with a solid track record.

Here are some factors to consider when evaluating thermal cameras:

Resolution

When considering a thermal camera, it is important to know the type of thermal core that it uses. The sensor determines the camera’s resolution and, in large part, its price. After considering the options, security practitioners must determine which thermal resolution is most appropriate for their application. For critical infrastructure deployments, where cameras need to be able to detect objects well beyond the fence line, premium thermal cameras with full thermal resolution of 640×480 are a must. These devices offer up to 16 times the number of pixels as a standard thermal device, delivering greater image detail, which is crucial for analytic performance at extended ranges.

When it comes to commercial installations that need wide-area monitoring and a detection range of 50 meters or less, however, 320×240 resolution is acceptable. Developed for small to medium-sized enterprises, these thermal cameras ensure that property size and security funding are no longer barriers to adoption. Remote storage companies and private marinas are some of the businesses now deploying thermal cameras for 24-hour wide-area monitoring and intrusion detection.

Detection Range

Long-range detection is another differentiator for high-end thermal cameras. These thermal cameras can detect an intruder before the suspect even reaches the perimeter and can send an alarm to the command center. This early detection gives security operators more time to respond. Pan-tilt-zoom (PTZ) thermal cameras, when integrated with other sensors like radar, improve tracking and threat assessment. When the radar detects a target, the PTZ thermal camera will “slew to cue” and capture video of the target’s exact location. The radar will continue to cue the PTZ camera on the target so that operators can maintain a visual at all times. For security systems that must address threats that can approach from all sides, at all times, advanced thermal cameras with longer detection ranges and PTZ capabilities are essential.

Analytics Capabilities

It is one thing to detect a threat, but it is quite another to classify that threat. In the era of artificial intelligence and machine learning, superior thermal cameras are delivering sharper images that, when coupled with video analytics, are improving the way security systems operate. No longer are security cameras simple “point-and-shoot” devices. Cameras enhanced by video analytics are able to differentiate between objects like foliage, vehicles, animals and humans. By providing precise detection of potential threats, thermal cameras with onboard video analytics offer automatic early warning to security personnel so they can intervene before a crime is committed.

Integration With Advanced Sensors

At the end of the day, a thermal camera is just a sensor operating within a security system. However, first-class thermal cameras will be able to integrate with other advanced sensors, delivering a higher level of perimeter monitoring and protection. Thermal cameras that integrate with radar are prime examples. Ground-based radars use radio waves to detect moving objects. They provide continuous coverage as they conduct 360-degree scans of a property every few seconds. By deploying a thermal-radar solution, operators increase redundancy and peace of mind, since if both a thermal camera and radar detect a human crossing the fence line, the likelihood that the event is a true alarm is higher. By using information from multiple sensors, operators gain enhanced situational awareness and can prioritize events and responses appropriately.

The Future of Thermal Technology

New applications and opportunities to deploy thermal cameras are growing in number every day. Thanks to new partnerships, the value of thermal is being extended beyond traditional use cases.

Utilities, for example, are deploying radiometric thermal cameras with temperature trending software so that substation operators can proactively inspect equipment and identify components that are at risk of overheating before they malfunction. This predictive maintenance not only reduces asset failure and the accompanying repair and replacement costs, but it also increases efficiency by reducing machinery downtime.

There has also been an increase in the number of drones equipped with both optical and thermal payloads and deployed to sites that are difficult to access. For critical infrastructure enterprises like oil and gas refineries, where assets are housed in remote areas, drones are a viable option to improve security surveillance. The advantage of drones is that they essentially act as mobile security cameras, and when equipped with thermal sensors, they can capture clear images and improve real-time intelligence at night. When integrated with state-of-the-art security systems, a drone, upon receiving a verified alarm, can be dispatched to an area of interest to quickly get eyes and ears on scene to assess the threat. As drones continue to gain traction in the security industry as an emerging technology, the number of thermal sensors deployed with them will likely increase.

Key Takeaways

The future for thermal technology is bright. Physically securing enterprises begins at the first line of defense – the perimeter. And thermal cameras have demonstrated their value as a superior perimeter protection technology through their ability to detect and classify threats in challenging lighting and weather conditions in which other cameras simply cannot perform. Security practitioners should remember to consider quality, total cost of ownership and track record of performance when evaluating thermal cameras. Not all thermal cameras are created equal, and selecting a reliable, high-performing product is key.

Fredrik Wallberg is the director of marketing for security for FLIR Systems.